All Categories

Featured

Table of Contents

- – Evaporative Cooler Pump Repair Sierra Madre, CA

- – Instant Air Solutions

- – Repair Swamp Cooler Sierra Madre, CA

- – Swamp Cooler Copper Line Repair Sierra Madre, CA

- – Evaporative Cooling Repair Sierra Madre, CA

- – Swamp Cooler Repair Near Me Sierra Madre, CA

- – Mobile Home Swamp Cooler Repair Sierra Madre...

- – Evaporative Cooler Repair Sierra Madre, CA

- – Swamp Cooler Line Repair Sierra Madre, CA

- – Evaporative Cooler Replacement Sierra Madre, CA

- – Swamp Cooler Line Repair Sierra Madre, CA

- – Evaporative Cooler Replacement Sierra Madre, CA

- – Evaporative Cooler Repair Near Me Sierra Mad...

- – Instant Air Solutions

Evaporative Cooler Pump Repair Sierra Madre, CA

Ensure appropriate upkeep and look for obstructions to prevent overheating and guarantee effective operation. A swamp cooler making a loud humming noise might be as a result of a malfunctioning motor, loose or damaged fan blades, or debris caught in the unit. Look for blockages, ensure all components are secure, and take into consideration specialist repair work if needed.

To evaluate a swamp cooler electric motor, transform off the power and check the motor for visible damage. Make use of a multimeter to look for connection in the windings and confirm voltage at the motor terminals. Make sure the capacitor and electrical wiring are operating appropriately. You could think your swamp cooler is falling short if it generates weak or no air movement, has an unusual sound, or if the air isn't cooling down efficiently.

Occasionally, the motor can't rotate due to the fact that the follower blade, blower wheel, or belt is jammed by debris or corrosion. Loose or busted circuitry, or a poor button or thermostat, can likewise stop power from getting to the electric motor. Always switch off the power initially, then inspect for obstructions, test the capacitor, inspect circuitry, and see if the motor transforms freely by hand.

Repair Swamp Cooler Sierra Madre, CA

Make certain the water supply valve to the colder is open so water can stream right into the pads. Switch on the pump switch to allow the water soak the pads for a couple of minutesthis helps the cooler work more efficiently. After the pads are wet, activate the fan or blower change to begin blowing cool air right into your area.

Constantly check that there suffices water in the storage tank and that the colder is tidy before use for finest efficiency. A clicking audio generally indicates loose components such as the follower blade, electric motor installs, or drive belt. It can also be triggered by debris inside the cooler hitting relocating elements.

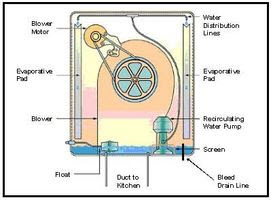

Evaporative colders, typically referred to as overload colders, are widely utilized in completely dry and warm environments to offer reliable and green air conditioning. At the heart of this system lies one of its most crucial components: the cooler electric motor. The electric motor plays an essential duty in making certain the proper feature of the whole unit by driving the fan that circulates air with the air conditioning pads and into the environment.

Swamp Cooler Copper Line Repair Sierra Madre, CA

As the air goes through these pads, it loses warm via the procedure of evaporation, causing colder, fresher air being distributed throughout the area or space. Without a working motor, the air circulation quits, rendering the cooler inefficient despite just how well various other parts are kept. Modern evaporative cooler motors been available in different kinds and power rankings, depending on the size and capability of the colder.

Many motors are geared up with thermal defense systems to prevent overheating and prolong their life expectancy. Like all mechanical parts, they are subject to put on and tear over time due to constant procedure, dust accumulation, or electrical issues. Typical indicators of motor failure consist of uncommon sounds, reduced air movement, or the total inability of the follower to spin.

The electric motor, being just one of the major mechanical elements, directly affects how well the system carries out under high-temperature problems. There are two primary sorts of electric motors used in evaporative colders: direct-drive motors and belt-driven motors. In a direct-drive system, the follower is mounted straight onto the motor shaft, resulting in less moving parts and much less maintenance.

Evaporative Cooling Repair Sierra Madre, CA

One of the most typical concerns with cooler motors is capacitor failure. The begin capacitor provides the initial electrical increase required to get the motor operating, while the run capacitor helps preserve smooth operation.

Dust and dirt accumulation can additionally bring about overheating and reduced motor lifespan otherwise cleansed consistently. To prevent expensive repairs or premature substitute, regular maintenance is essential. This includes cleansing the motor housing, looking for loose connections, evaluating the capacitor, and making certain appropriate air flow around the system. It's likewise crucial to switch over off the power prior to examining or servicing the motor to stop electric shock or damage to the internal electrical wiring.

Specialist fixing solutions can swiftly determine the origin of the issue, whether it's a faulty electric motor, damaged capacitor, or an additional related part, and give an effective service to restore your air conditioning system to full capability. In recap, the motor is the driving pressure behind any evaporative cooler. Without an effectively working motor, the whole cooling process breaks down, leaving you without relief from the warm.

Swamp Cooler Repair Near Me Sierra Madre, CA

In 1945 R C Gorman and his son, Paul started a made use of home appliance company that got on Henshaw Road in Phoenix, AZ. In time the business transformed right into a furnishings company. They would certainly take a trip to other states to obtain distressed and liquidated furnishings and resell it. About this moment evaporative colders were becoming preferred.

He included a sheet metal store, and out of an automobile, motor developed a device to put louvers in sheet metal. Paul and Betty's children, Robert and David functioned at the company as soon as they were large sufficient.

Mobile Home Swamp Cooler Repair Sierra Madre, CA

Paul sold the residential or commercial property to the state of Arizona, with the condition that he can maintain ownership of the home until building and construction of the highway started. He bought home on 35th Opportunity, simply south of Thomas and built a brand-new store/sheet metal shop, together with a couple of rental spaces.

In 1984, David and his other half, Pam (who had started functioning at the store in 1974) bought the service from Paul and Betty. A couple of years later, they appropriated both of the rental units and used the whole building for Gorman Colder Supply.

Overload coolers are a wonderful option for homes in some areas and particularly for older homes, however not all homes are excellent for cooling by a swamp cooler (Swamp Cooler Repair Company Sierra Madre). Modern a/c unit are usually the preferred selection for house owners purchasing older and newer homes. With that stated, there are lots of reasons that home owners ought to consider removing their swamp cooler and changing to a much more contemporary method of cooling their home

Swamp coolers can be eliminated due to issues that might develop after they have actually gotten old or since the homeowner wants to improve their cooling system. After a while swamp coolers can encounter problems such as deterioration and water damages, not cooling down the home adequately, and water leaks. Every one of these problems can create troubles with the roofing and the structure of the home if the damage expands past the roofing system.

Evaporative Cooler Repair Sierra Madre, CA

An additional failure of overload colders is the quantity of maintenance it takes to keep them running smoothly and for a very long time. Modern a/c unit call for much less repair and maintenance and usually last longer than typical swamp coolers. Overload coolers are not constantly dependable and it can be additional discouraging when it is the middle of the summer and the heat is soaking right into your home.

There is not a simple response to this inquiry due to the fact that all of it relies on your preferences and what your needs are for your home and structure. It likewise depends on why you are wishing to eliminate your swamp cooler because it no more functions well or since you intend to upgrade your air conditioning system to something much more ideal for your home.

There are many various points that can be done by the property owner to obtain rid of these remnants and cover up the unpleasant space left. This opening can additionally allow leaks and sunshine to show with right into the space of the attic and top level rooms. The alternatives for a cover can include: roofing system spots, putting in a sunroof, and setting up a skylight.

Swamp Cooler Line Repair Sierra Madre, CA

The right choice might additionally change depending upon why you are eliminating the swamp cooler, whether it is to upgrade to a contemporary air conditioning system or one more reason. This is among the most typical choices for fixing the roofing following the elimination of an overload cooler and can be done by a specialist roof covering firm.

The patching product will be matched to the existing roof covering and roof shingles. When a swamp cooler is removed there are typically numerous ventilation openings left that numerous individuals determine to develop into sunlight tubes. This way they are sealed off however the sunlight can still come through. There are several kinds of skylights including ones that open and close online and others that just simply allow more sunshine into the upper areas.

Evaporative Cooler Replacement Sierra Madre, CA

An additional choice that property owners can do is to mount an attic follower to supply the required air movement into the attic. This is commonly a simple and really budget-friendly fix since the electrical connections are currently in position, the opening usually just requires to be changed. Swamp colders can truly leave a whole lot of concerns with the roof covering and ceiling below where the system went to.

If you have any kind of concept what parts comprise an overload cooler, determining the source of the malfunction ought to not be too tough. Following are the swamp cooler components most susceptible to face issues: Two main types of electrical troubles can affect swamp colders. The first type is faulty circuitry.

Swamp Cooler Line Repair Sierra Madre, CA

When an abnormal amount of electricity moves right into your cooler due to faulty circuitry, the system may wind up with a blown fuse (Swamp Cooler Repair Company Sierra Madre). Swamp colders likewise act up when they are not receiving sufficient electrical power. For such a thing to occur, you may have plugged the cooler right into a damaged electrical outlet or one that is not made for the colder

If your colder is not blowing air out hard sufficient, one issue can be the lack of exhaust. To be able to do its task, an evaporative cooler requirements adequate air flow and circulation. The ducts in the room where the colder is set up should be able to supply enough exhaust.

In case there is no air blowing out of the colder at all, there might be an issue with the pump. You can also make additional sure by checking the integrates and brokers to see if they are blown or tripped. In such a case, thermostats can also be taken into consideration.

Evaporative Cooler Replacement Sierra Madre, CA

The humming audio suggests that the motor is obtaining power but isn't turning. An additional possibility is that the electric motor's bearings are taken or there's particles blocking the follower blades.

When your colder is not blowing out cold air, you can expect three primary problems. Swamp coolers need a resource of fresh air. If you think interior air can do the job, you are in the incorrect. The cooling can also be impacted when the air in your area is excessively damp.

Evaporative Cooler Repair Near Me Sierra Madre, CA

When your area is moist, the air currently has also much water vapor, and that means the water in the cooler can not evaporate. If the pads are not saturated sufficient, the colder will certainly not be able to generate cold air.

Instant Air Solutions

Address: 412 W Dryden St Apt 6 Glendale, CA 91202Phone: (747) 307-6363

Email: instantairsolutionsinc@gmail.com

Instant Air Solutions

Below are several of one of the most usual issues that can be troubleshot, either by you by yourself or a professional. Swamp colders have less electronic parts compared to a/c unit. Because of that, you can expect the most common reason for the electric motor going poor to be a blown fuse.

Evaporative Cooler Rust Repair Sierra Madre, CASwamp Cooler Repair Contractors Sierra Madre, CA

Evaporative Cooler Repair Near Me Sierra Madre, CA

Swamp Cooler Repair Near Me Sierra Madre, CA

Evaporative Cooling Repair Sierra Madre, CA

Near You Seo Company Near Me Sierra Madre, CA

Local Seo Plans Sierra Madre, CA

Swamp Cooler Repair Company Sierra Madre, CA

Instant Air Solutions

Table of Contents

- – Evaporative Cooler Pump Repair Sierra Madre, CA

- – Instant Air Solutions

- – Repair Swamp Cooler Sierra Madre, CA

- – Swamp Cooler Copper Line Repair Sierra Madre, CA

- – Evaporative Cooling Repair Sierra Madre, CA

- – Swamp Cooler Repair Near Me Sierra Madre, CA

- – Mobile Home Swamp Cooler Repair Sierra Madre...

- – Evaporative Cooler Repair Sierra Madre, CA

- – Swamp Cooler Line Repair Sierra Madre, CA

- – Evaporative Cooler Replacement Sierra Madre, CA

- – Swamp Cooler Line Repair Sierra Madre, CA

- – Evaporative Cooler Replacement Sierra Madre, CA

- – Evaporative Cooler Repair Near Me Sierra Mad...

- – Instant Air Solutions

Latest Posts

Tankless Hot Water Heater Installation Near Me Leucadia

Del Mar Plumber Gas Line Repair

Santee Pipe Repair Plumber

More

Latest Posts

Tankless Hot Water Heater Installation Near Me Leucadia

Del Mar Plumber Gas Line Repair

Santee Pipe Repair Plumber