All Categories

Featured

Table of Contents

- – Rv Roof Maintenance Atwood, CA

- – OCRV Center

- – Repair Rv Roof Atwood, CA

- – Rv Roof Repair Near Me Atwood, CA

- – Rv Roof Repair Fiberglass Atwood, CA

- – Epdm Rv Roof Repair Atwood, CA

- – Rv Roof Maintenance Atwood, CA

- – Rubber Roof For Rv Atwood, CA

- – Rv Fiberglass Roof Repair Atwood, CA

- – Rubber Roofing For Rv Atwood, CA

- – Rv Rubber Roof Repair Atwood, CA

- – Epdm Rv Roof Repair Atwood, CA

- – Rv Roof Maintenance Atwood, CA

- – Rv Rubber Roof Maintenance Atwood, CA

- – Rubber Roof For Camper Atwood, CA

- – OCRV Center

Rv Roof Maintenance Atwood, CA

As you can see from the significant result of an inadequately maintained seam in the video embedded above, any type of joints on Motor homes need to be on a regular basis examined for the stability of the sealant. All you need apart from a putty blade to aid with the elimination of the old Dicor is a tube of Dicor and a caulk weapon.

Know plainly what is and is not covered by your RV insurance coverage, and ask just how to get the coverage you desire, depending on its cost. Where recreational vehicle roof leakages are concerned, it might depend on the means the damages occurred. For instance, insurance provider DENY cases on the damages that happens from leaks that are taken into consideration to be maintenance-related.

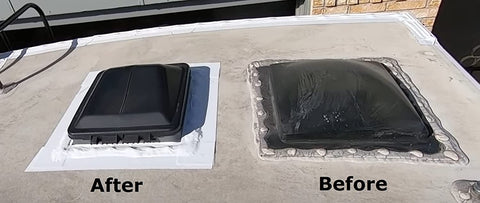

Dicor sealant that is broken such as this from direct exposure to the sun and other climate needs to be replaced. It's a simple and worthwhile job. A fast check of the sealant around vents, followers, photovoltaic panels, air conditioning unit, and antennas every thirty day approximately keeps our RV roof in terrific problem, preventing possibly pricey leaks.

Repair Rv Roof Atwood, CA

Once again we motivate you to speak to your insurance coverage representative regarding your coverage. Recreational vehicle roof covering leakages can be actual mischief-makers. Discovering how to stop them in the initial area is your absolute best defense against possibly significant damages to your recreational vehicle, and also to your health and wellness. Join our newsletter to find out about all points RV-related.

Whether this is your very first time when driving or you're an experienced expert, we 'd like for you to geek out with us!.

Rv Roof Repair Near Me Atwood, CA

Having a recreational vehicle uses flexibility and experience, however it additionally comes with a fair share of upkeep obligations. Among one of the most critical jobs for recreational vehicle owners is maintaining the honesty of the roof covering. A leaky RV roof covering can bring about extensive interior damages, mold and mildew growth, and even architectural concerns if left without treatment.

Otherwise addressed, water breach can bring about: Delamination of walls and ceiling By carrying out normal assessments and recognizing how to manage recreational vehicle roof fixing, you can extend the life of your lorry and stay clear of expensive damages. Before you can take care of a leakage, you need to find it. This can be trickier than it seems, as water usually takes a trip far from the entry point prior to revealing visible signs.

Try to find cracks, soft spots, leaks, or deteriorated caulking around joints, vents, skylights, and antennas. Take a look at the sides of the roof where it satisfies the wall surfaces. These areas are specifically vulnerable to leaks. Inside the recreational vehicle, seek discoloration or sagging in the ceiling. Examine around roof-mounted devices for indicators of water.

Consider utilizing a liquid roofing system finishing: Mask off locations not to be covered. Mix and pour the covering equally throughout the roof covering.

Rv Roof Repair Fiberglass Atwood, CA

Clean every 3-6 months, depending on usage and storage. Stay clear of car park under trees where limbs and sap can harm the roof. While lots of RV roofing fixings can be DIY tasks, some scenarios need professional help: Structural damage or significant roof sagging Big, covert leakages that are hard to map Full membrane replacement Insurance-related repair services Discovering just how to execute a RV roofing repair encourages you to protect your investment, conserve cash, and prevent mid-trip catastrophes.

If you do not inspect, reseal, and fix your recreational vehicle roof covering frequently, you will certainly end up with some attractive terrible water damages. This is something that will promptly decrease the value of your motor home and might also render it unusable. Fortunately, taking treatment of your recreational vehicle roof is something you can possibly do all on your own.

After concerning 10 years, it will additionally be needed to reseal the entire roof covering. To do this, you'll require to climb onto the roof, yet be very careful when you do. Are you sure it's solid enough to sustain you? Is there a ladder at the back? Otherwise, it most likely isn't strong enough to be walked on.

Epdm Rv Roof Repair Atwood, CA

Next off, you'll desire to cleanse your roofing completely, so regarding get rid of any type of dirt bits. You can use a long taken care of brush for this, yet never utilize a cleaner that includes oil solvents or citrus components on your rubber or vinyl roof covering. These types of cleansers will cause irreversible damages to the surface area.

While you're cleaning up, remove any debris or old roofing system material, however be cautious while you do this as you could easily extend a tear, or perhaps punch an opening with the roofing system. You need to after that dry out the roof covering as best as you can. Note: Rubber motor home roof coverings can be extremely unsafe when damp.

After the roofing is clean, you are mosting likely to intend to examine the joints for holes, fractures or peeling off, so you can reseal any place needed. On top of that, you'll wish to resolve resealing all seams when a year whether or not they reveal indications of wear.

Rv Roof Maintenance Atwood, CA

When it comes to selecting the most effective motor home roof covering sealant, you'll intend to take into consideration whether you are repairing a tear, resealing a seam, or securing the entire roofing system. The kind of roof is likewise important to keep in mind, as RV roofs can be made from either EPDM (Ethylene Propylene Diene Monomer) and TPO (Thermal Polyolefin) and you need the product you use to be suitable with your roof covering type.

Dicor Self-Leveling Lap Sealant is a good option for reviewing old roofing seals. It can be utilized for area sealing or to reseal every joint on the RV roofing system. Just clean the area well and use with a caulk weapon. The things will certainly level itself out, so do not bother with that part.

Rubber Roof For Rv Atwood, CA

This tops and layers the roofing to develop a wonderful, protective coating that'll last for several years. Ultimately, there is the Dicor TPO Roofing System Finish System. Similar to the EPDM system detailed above, this finish item will certainly cover your TPO roofing system and help it last another ten years. Prior To EPDM and TPO, steel was the product of selection for motor home roofings.

The aforementioned EternaBond is still king when it concerns repairing small damages on a metal roof covering. It also works well for sealing joints. Recreational vehicle steel roofs do require to be absolutely resealed every so often. Family roof covering coatings will certainly seal a steel roofing system simply fine, but the finest item without a doubt, for metal roof coverings, is Dicor Steel Recreational Vehicle Roofing System Finishing.

Dicor Self-Leveling Lap Sealer works well for this task. You'll need to eliminate the existing roof covering.

Check plywood for rot, bowing, mold and mildew, or splintering. Change harmed items.

Rv Fiberglass Roof Repair Atwood, CA

Do this in small chunks the whole time the roof covering, cutting openings in the rubber roof covering for any kind of function that will certainly go back into the roof covering. Lastly, change your roofing system's followers, skylights, and air conditioning system. Seal each seam with the lap sealant we discussed earlier. You'll additionally intend to apply lap sealer to the sides of the roofing system.

In this blog post, we want to share with you just how to Do it yourself Recreational vehicle roofing system repair work. Recognizing exactly how to DIY a lot of the points that can damage or mess up will certainly save you not just a whole lot of money on Recreational vehicle repair services however might additionally save you a lot of possible time in the shop!

Rubber Roofing For Rv Atwood, CA

I may receive a tiny compensation when you buy utilizing my web link. Review our Please Note Plan for even more information. We try to plan our routes meticulously to stay clear of low-hanging items over the roadway. Often, though, we discover ourselves in unplanned circumstances. This is just how we wound up with a couple of small tears on the roof of our motor home.

We believed we were free from the branches, but we wound up catching a few of them on the far left side of the roofing. There were a total of 4-5 tiny holes in the side of the roofing system. We really did not inspect the roof covering due to the fact that we really did not believe we hit anything.

Among the splits in our motor home roofing A couple of weeks later on, we endured a severe electrical storm and a whole lot of rainfall. Throughout the tornado, we located that we had a small quantity of water leaking with one of the lights in the bathroom. Thankfully, we did not end up with any permanent water damages.

Rv Rubber Roof Repair Atwood, CA

He patched it as ideal he could with heavy-duty gorilla tape and then purchased the materials required to do a recreational vehicle roof covering repair work. The EPDM rubber roofing product that many RVs come with is usually pretty difficult as far as roofing materials go. Rubber roof coverings last for several years, yet they do tear if captured hard enough.

In our instance, this meant eliminating the gorilla tape that we had actually used as a short-term fix while we awaited the products we ordered to arrive. You'll intend to clean the area around the tear that you will certainly be covering well. This enables the spot to correctly adhere and will certainly protect against future leaks.

To clean up the roofing system, utilize scrubing alcohol and either a dustcloth or paper towels., which is a RV roof fixing tape.

You will certainly desire to distribute just how much you require and cut a piece accordingly. Remove the backing and use meticulously over the tear in the roof covering. Once it has actually touched the roof covering, it adheres pretty quickly, so you'll intend to see to it and position it right the very first time.

Epdm Rv Roof Repair Atwood, CA

Press strongly and continue to scrub it and ravel the patch for a number of minutes. Making use of a caulk gun, layer the whole patch with Dicor 501LSW-1 Epdm Self-Leveling Lap Sealant. This rubber sealant produces a safe secondary seal on your rubber roof covering and makes sure that the leakage is properly sealed.

There are a great deal of Dicor recreational vehicle roofing repair work items that you can buy consisting of roofing finishes, roof covering sealer, and a lot more for the surface area of your roofing. Applying the Dicor lap sealer Begin on the sides and work your method around the whole spot, completing the center as you go.

Wipe any excess off and do not allow it to run down too much. This is a self-leveling sealant so you must end up with a rather level patch (Rv Roof Leak Repair Atwood). According to the producer, it will certainly be water-proof in 4 hours, 80% cured in 48 hours, and 100% healed in one month

Rv Roof Maintenance Atwood, CA

To replace a whole motor home roofing with considerable damages would cause far more pricey repair work. I really hope that you have located the info in this article useful. Make certain and pin this article for future recommendation in instance you might require it later on! To stop motor home roof covering issues, inspecting your roof consistently during RV maintenance is a great idea.

Your RV is a home on wheels, whether for a number of days at once or throughout the year. Like a home, the water supply can leakage, such as the fresh water tank or the hot water heater. A motor home is also more prone to specific leaks, such as in the roofing system, because it is mobile and has an extra light-weight design than your home.

Your Recreational vehicle is a substantial investment. Here are a few reasons assessments and repair work matter: When you check your Recreational vehicle on a regular basis, you can catch concerns like leakages before they trigger considerable damages to your inside.

Rv Rubber Roof Maintenance Atwood, CA

Water dripping from the a/c device outside the RV is normal throughout operation. The water ought to follow a specific path down the networks on the roofing system that lead it to either the forward or aft corner of the gear. If you see water trickling inside or leaking in an additional location outside, that could symbolize an issue with the system.

Plumbing leaks can show up in the storage area. Sometimes, water damage presents obvious indicators, however you might not observe it immediately in other situations.

Before you begin the procedure of camper leak fixing, you require to find the resource. Comply with these steps to identify the leak's beginning point: Inspect the roofing system, wall surfaces, ceilings and doors to discover any locations with used or split seals and caulking.

Run water via the faucets and examine for trickling water at the connections. Examine wastewater and freshwater systems for fractures or leakages in the containers, connections and tubes.

Rubber Roof For Camper Atwood, CA

OCRV Center

Address: 23281 La Palma Ave Yorba Linda, CA 92887Phone: (714) 909-1444

Email: art@ocrvcenter.com

OCRV Center

Spray certain areas while someone else stands inside the camper to see where water enters. A flashlight lights up the area for a lot more effective assessment in cramped, dark locations like cupboards and plumbing fixtures. This gadget attaches to hose pipes to look for uncommon pressure drops that might show a leak.

Rv Repair Shops Near My Location Atwood, CAMotorhome Repair Service Atwood, CA

Rv Repair Places Near Me Atwood, CA

Rv Repairs Near Me Atwood, CA

Motorhome Repair Shop Atwood, CA

Best Rv Repair Near Me Atwood, CA

Rv Plumbing Repair Near Me Atwood, CA

Rv Repair Centers Near Me Atwood, CA

Rv Repair Services Near Me Atwood, CA

Rv Solar Installation Atwood, CA

Rv Repairs Near Me Atwood, CA

Rv Repair And Service Near Me Atwood, CA

Rv Repair Services Near Me Atwood, CA

Motorhome Awning Repair Atwood, CA

Rv Repair And Service Near Me Atwood, CA

Rv Solar Panel Installation Atwood, CA

Rv Service And Repair Near Me Atwood, CA

Rv Ceiling Repair Atwood, CA

Rv Generator Repair Atwood, CA

Rv Service And Repair Near Me Atwood, CA

Rv Floor Repair Near Me Atwood, CA

Rv Mechanics Near Me Atwood, CA

Full Service Rv Repair Near Me Atwood, CA

Rv Mechanics Near Me Atwood, CA

Rv Service Repair Near Me Atwood, CA

Rv Floor Repair Near Me Atwood, CA

Motorhome Refrigerator Repair Atwood, CA

Rv Mechanics Near Me Atwood, CA

Rv Plumbing Repair Near Me Atwood, CA

Full Service Rv Repair Near Me Atwood, CA

Rv Solar Installation Atwood, CA

Rv Repair Shops Near My Location Atwood, CA

Rv Floor Repair Near Me Atwood, CA

Rv Generator Repair Atwood, CA

Rv Repair Shops Near My Location Atwood, CA

Rv Repair Shops Near My Location Atwood, CA

Full Service Rv Repair Near Me Atwood, CA

Rv Repair Places Near Me Atwood, CA

Rv Mechanics Near Me Atwood, CA

Rv Repair In My Area Atwood, CA

Rv Repair Centers Near Me Atwood, CA

Motorhome Repair Near Me Atwood, CA

Rv Repair In My Area Atwood, CA

Rv Service And Repair Near Me Atwood, CA

Rv Repair Services Near Me Atwood, CA

Best Rv Repair Near Me Atwood, CA

Motorhome Repair Shop Atwood, CA

Motorhome Repair Near Me Atwood, CA

Rv Repair Service Near Me Atwood, CA

Best Rv Repair Near Me Atwood, CA

Rv Repair Services Near Me Atwood, CA

Motorhome Generator Repair Near Me Atwood, CA

Rv Repair Places Near Me Atwood, CA

Rv Repair In My Area Atwood, CA

Rv Solar Panel Installation Atwood, CA

Rv Generator Repair Atwood, CA

Rv Generator Repair Atwood, CA

Motorhome Generator Repair Near Me Atwood, CA

Motorhome Repair Shops Atwood, CA

Motorhome Generator Repair Near Me Atwood, CA

Motorhome Repair Shops Atwood, CA

Motorhome Repair Near Me Atwood, CA

Rv Solar Installation Atwood, CA

Rv Floor Repair Near Me Atwood, CA

Motorhome Repair Service Atwood, CA

Motorhome Generator Repair Near Me Atwood, CA

Motorhome Awning Repair Atwood, CA

Motorhome Repair Near Me Atwood, CA

Rv Plumbing Repair Near Me Atwood, CA

Rv Delamination Repair Near Me Atwood, CA

Rv Plumbing Repair Near Me Atwood, CA

Camper Ac Repair Near Me Atwood, CA

Motorhome Refrigerator Repair Atwood, CA

Camper Ac Repair Near Me Atwood, CA

Motorhome Awning Repair Atwood, CA

Rv Solar Panel Installation Atwood, CA

Rv Service And Repair Near Me Atwood, CA

Rv Repair In My Area Atwood, CA

Near Here Seo Management Atwood, CA

Near Me Seo Services Near Me Atwood, CA

OCRV Center

Table of Contents

- – Rv Roof Maintenance Atwood, CA

- – OCRV Center

- – Repair Rv Roof Atwood, CA

- – Rv Roof Repair Near Me Atwood, CA

- – Rv Roof Repair Fiberglass Atwood, CA

- – Epdm Rv Roof Repair Atwood, CA

- – Rv Roof Maintenance Atwood, CA

- – Rubber Roof For Rv Atwood, CA

- – Rv Fiberglass Roof Repair Atwood, CA

- – Rubber Roofing For Rv Atwood, CA

- – Rv Rubber Roof Repair Atwood, CA

- – Epdm Rv Roof Repair Atwood, CA

- – Rv Roof Maintenance Atwood, CA

- – Rv Rubber Roof Maintenance Atwood, CA

- – Rubber Roof For Camper Atwood, CA

- – OCRV Center

Latest Posts

Family Photos Colton

Eastvale High School Senior Photography

Concord Stamped Concrete Patio Contractors

More

Latest Posts

Family Photos Colton

Eastvale High School Senior Photography

Concord Stamped Concrete Patio Contractors